I really think that at this point, the issue has to do with morphology of the particle shape. I think that using a spray dried particle may solve this issue, as spray dried material is granular and will “roll” much better.

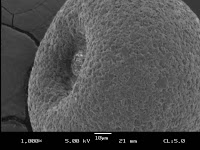

SEM images of a porcelain body I had spray-dried earlier this year (thanks Gary!).

We have a couple of spray driers. One is very high-tech and is used for nano-powder preparation. If I use it, it will require absolute cleaning after use (probably a few hours worth of work) as clay bodies are not normally passed through it and it requires total sterilization for its normal day-to-day use. The other spray drier is better suited to my needs as it is used with clay bodies on a regular basis. Neither of these are options till Tuesday. In the meantime, it would be nice to approximate what I will get. I just happen to have about 100 lbs of spray dried material (sometimes being a pack rat is a good thing!). Not sure what the recipe for it is, though I think it’s probably a bone china recipe from Lennox China. A quick test revealed that some of it passes through a 200 mesh screen. Time for some more screening!

Before I go on, here is a useful chart that gives a picture of relative and absolute sizes:

No comments:

Post a Comment