Before I begin, I want to thank Mark Ganter and the good people he works with. Mark may not be the first person to develop Rapid Prototyping techniques in ceramics but he is the first person I’ve come across who has made his findings publicly available. He has done so through a phenomenal website which can be found here…

http://open3dp.me.washington.edu/

If you are interested in Rapid Prototyping ceramics, his website is mandatory reading!

Prior to Mark, the few people working in this field guarded their work at all costs. Mark’s open disposition is both refreshing and inspiring.

This blog chronicles what I learn as I go along. Its a way for me to share what I learn in the hopes of giving something back to Mark and to anyone else who's interested.

Mark's research includes using a commercially prepared casting recipe from SPS (Seattle Potter's Supply). I assume this recipe is fairly open in structure to allow for fast drying. I've made up a white body with an average SSA (Specific Surface Area) which should get me in the same ballpark. There are a couple of concerns here: the body should dry fairly quickly and should have good strength. I'm hoping that the SSA I'm targeting will allow for decent drying rates. I could try to maximize dry strength by using fine clays but this may retard drying rates. Instead, I will rely on the addition of sugar and Maltodextrin for its green strength…

CDF P-MF Cone 6 Porcelain

Tile 6 9.89

EPK 9.89

Grolleg 30.77

Flint 24.18

NC-4 19.78

Frit 3124 5.49

Total 100 %

SSA: 9.12

Quartz: 1.22

Glass: 80.35 %

Clay: 50.55 %

Cone: 6

I made a 37,500 g batch dry, added to 25lbs water and blunged it with a high-speed, high-shearing Shar mixer untill it was hot (this filled about 1/2 of a 20 gallon brute can).

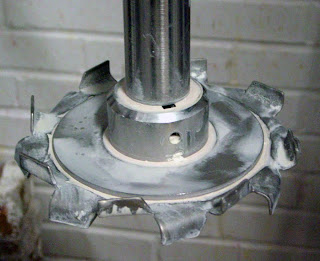

Our Shar mixer with a detail of its high-shearing blade.

No comments:

Post a Comment